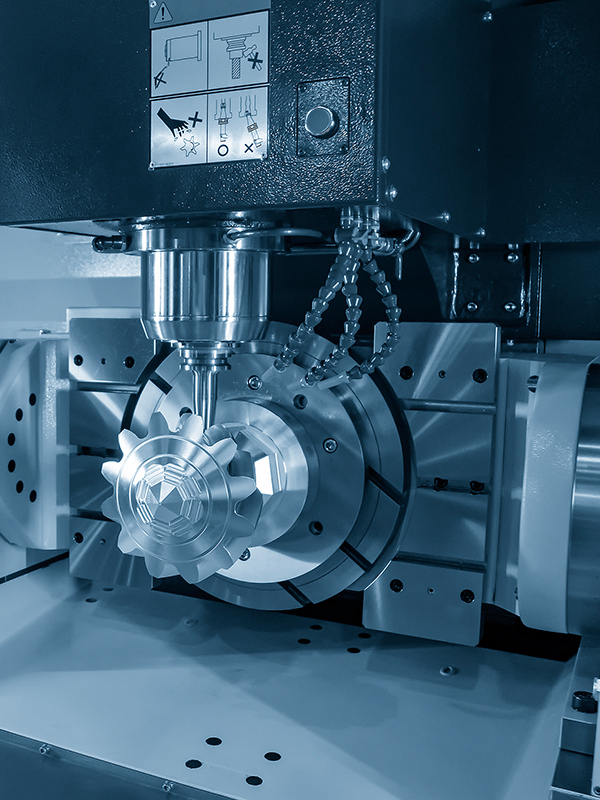

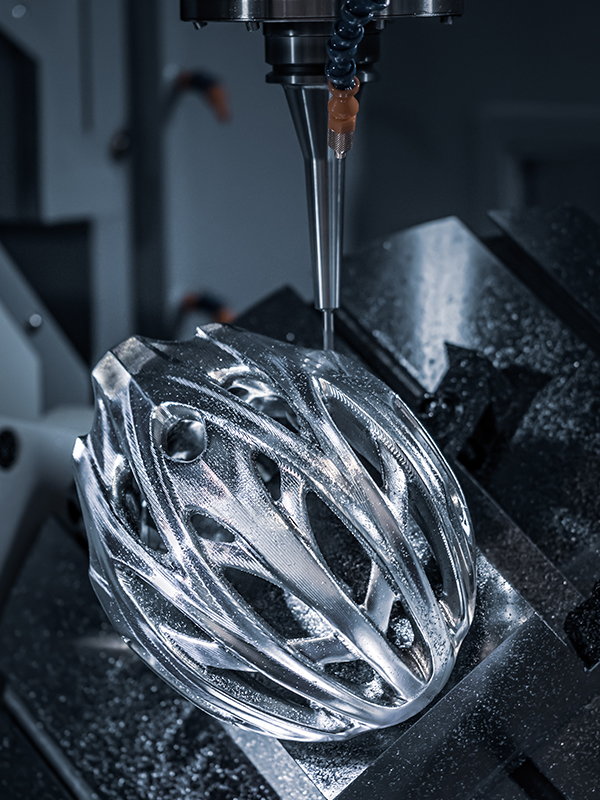

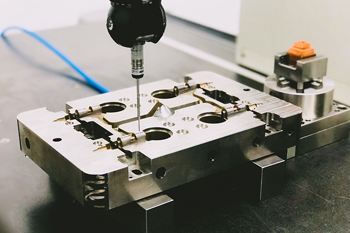

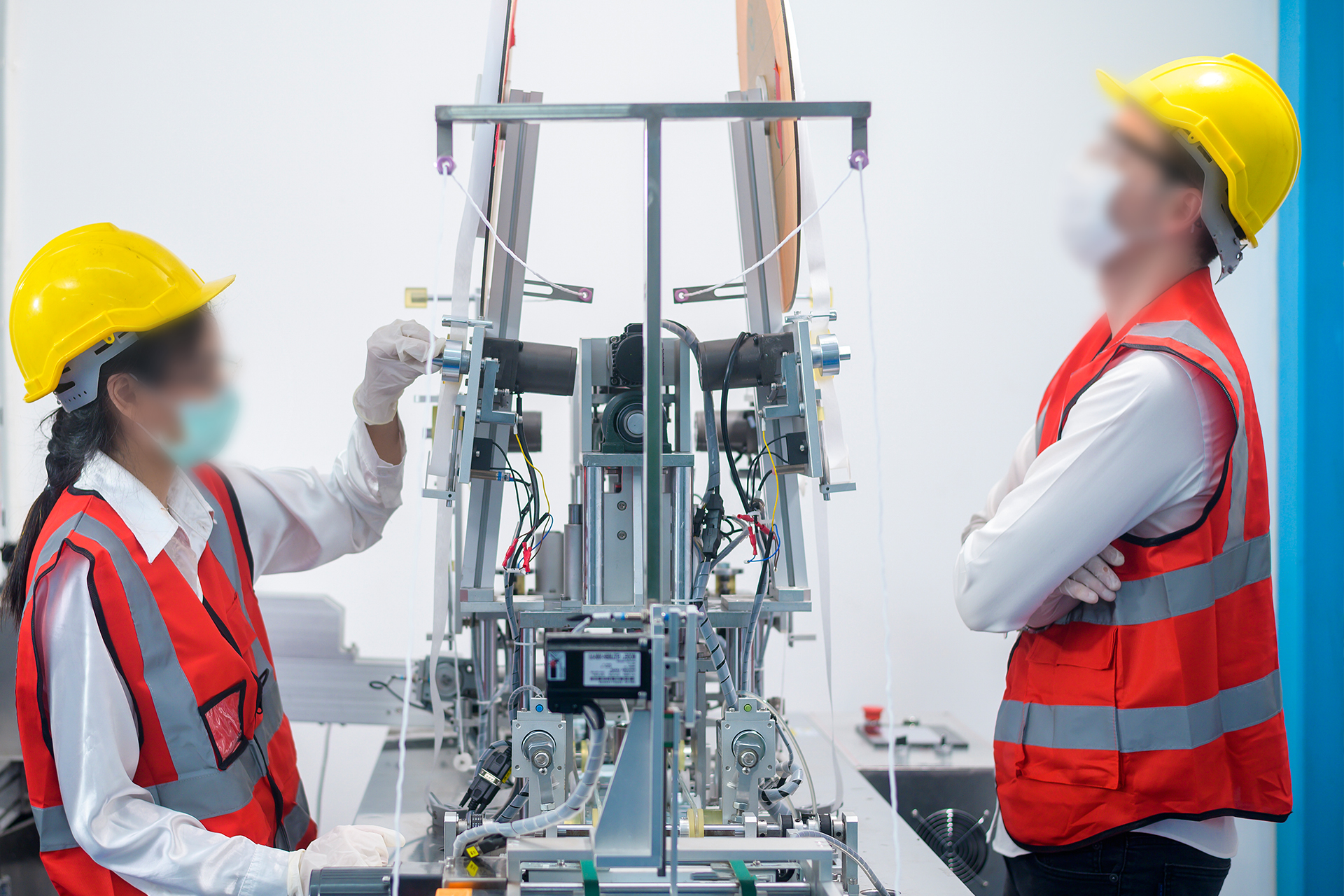

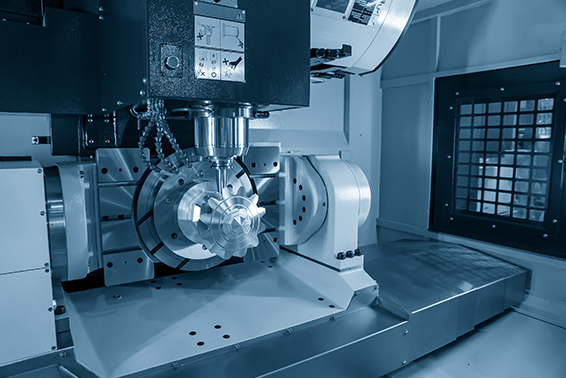

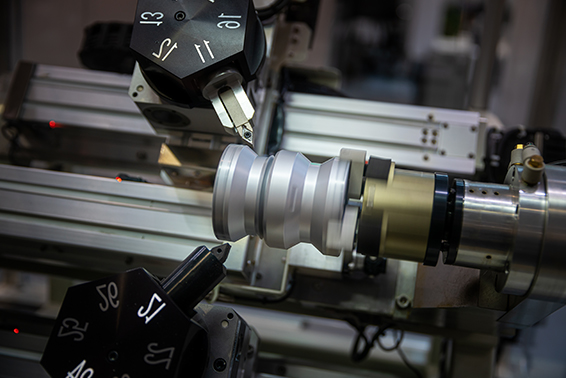

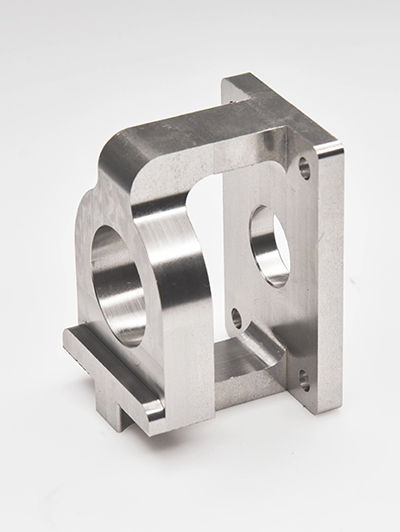

When mission-critical components demand uncompromising precision, our 18 ISO-certified CNC systems (including 5-axis DMG MORI DMU 65 and Sodick AQ550L Wire EDM) deliver:

Zero-defect machining for high-risk applications

Material mastery from Inconel 718 to PEEK implants

Full traceability compliant with FDA 21 CFR Part 11"

Autonomous Driving Radars | Mirror Surface Ultra-Precision Machining (Ra≤0.1μm): 20% Longer Detection RangeAut...